Why Will Kraft Cushion Paper Become The Main Force in Express Packaging?

- Categories:News

- Time of issue:2021-10-19 09:36

摘要:Among the express packaging materials, plastic packaging materials used 851,800 tons, accounting for nearly 10% of express packaging materials, the difficulty of recycling plastic products far exceeds that of paper. At this stage, it is appropriate to promote the use of cushion paper packaging to replace plastic packaging consumables.

Why Will Kraft Cushion Paper Become The Main Force in Express Packaging?

摘要:Among the express packaging materials, plastic packaging materials used 851,800 tons, accounting for nearly 10% of express packaging materials, the difficulty of recycling plastic products far exceeds that of paper. At this stage, it is appropriate to promote the use of cushion paper packaging to replace plastic packaging consumables.

- Categories:News

- Time of issue:2021-10-19 09:36

Among the express packaging materials, plastic packaging materials used 851,800 tons, accounting for nearly 10% of express packaging materials, the difficulty of recycling plastic products far exceeds that of paper. At this stage, it is appropriate to promote the use of cushion paper packaging to replace plastic packaging consumables.

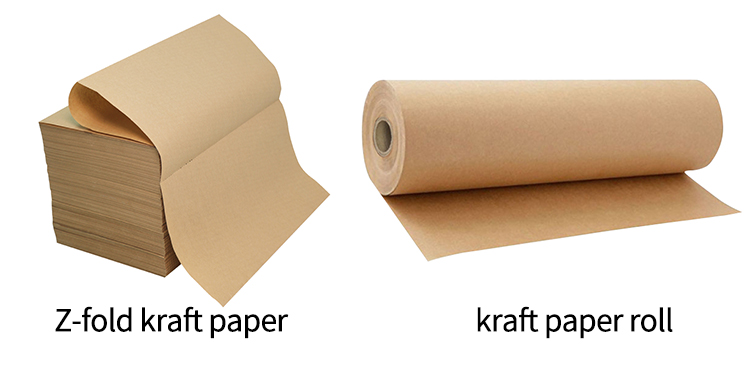

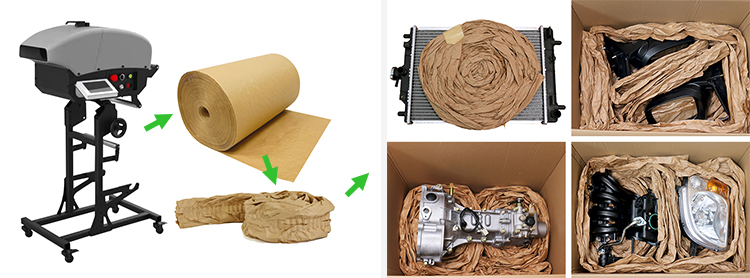

There are many choices of paper pads, some paper pads can withstand 60 kg of heavy items, such as equipment, auto parts, etc. There are also lightweight items such as cosmetics, luxury goods, etc, all can packed with cushion paper. Folding cushion paper and roll cushion paper can fill the packaging gaps well, avoid items that are damaged due to shaking during transportation, achieve the effect of cushioning and shock absorption.

Can be used with WiAIR P100pro paper cushion machine

The honeycomb paper becomes three-dimensional after being stretched. Use with lining paper to avoid minor scratches.It can also be used to fill gaps in item packaging and play a decorative role.

Can be used with WiAIR HC20 Electric Honeycomb Paper Cushion Machine

The three-fold roll paper is made of high-strength 80g kraft paper, which is made of single-layer or double-layer paper folded in half on both sides, extruded by paper pad machine to form 3D three-dimensional folds. Place the cushion kraft paper in the space between the origami, for cushion protection. It has higher compressive strength and elasticity when rolled into a disk shape. It can withstand heavy objects within 60KG, packing heavy objects such as auto parts, automobile engines, motors, water pumps, etc., also has the protective effect of filling, buffering and wrapping.

A large part of the plastic packaging consumables used on the market are non-degradable materials, they cannot be recycled and reused, causing great pollution to the environment. Compared with plastics, paper materials are more environmentally friendly and biodegradable. They can be reused many times and have recycling value. The paper used as paper cushion is not made of any plant, it made of high-strength conifers. The cushion paper made of conifer has high fiber strength, not easy to break and more resistant to pressure, durability and impact than plastic. Coniferous trees are specially planted, with the permission of the state, logging is carried out in a planned and regular manner to achieve the goal of environmental protection.

The cushion paper not only has advantages over plastic consumables in terms of environmental protection, but also has a high packaging effect. It can pack items of various materials, either filling or wrapping, it can be used in many scenarios. Under the government's environmental protection policy, it is believed that the cushion paper packaging will completely replace plastic packaging in the future!